O Series

The main feature of the O series is the oil bath motor. Together with its robust cast iron structure, it makes this model particularly reliable even in very tough operating conditions.

Simple and rational construction allows easy access for maintenance. As a result, even after its market launch in 1977, the O series continues to meet the requirements of the most demanding customers.

This serie includes models with vortex impeller (DGO) which is recommended for use in soiled liquids and with multi-channel impeller (DRO) for lifting clean or slightly soiled water.

Each model undergoes pressurised test to ensure that the motor compartment is airtight and the mechanical seals are fitted correctly, to guarantee excellent reliability.

DG [DRAGA]

- Cast iron vortex impeller

- Full free passage

- Sewage

- Soiled wastewaters with solids

- Lifting stations in small civil and residential plants

DR [DRENO]

- Cast iron multi-channel open impeller

- Stainless steel suction strainer

- Clear or slightly soiled wastewaters

- Strained, seepage and underground pump-out waters

- Irrigation and pumping from wells and reservoirs

Details

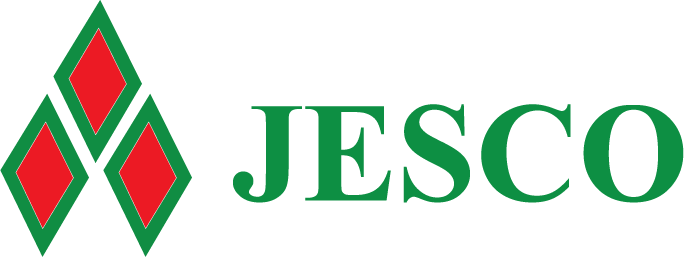

Handle

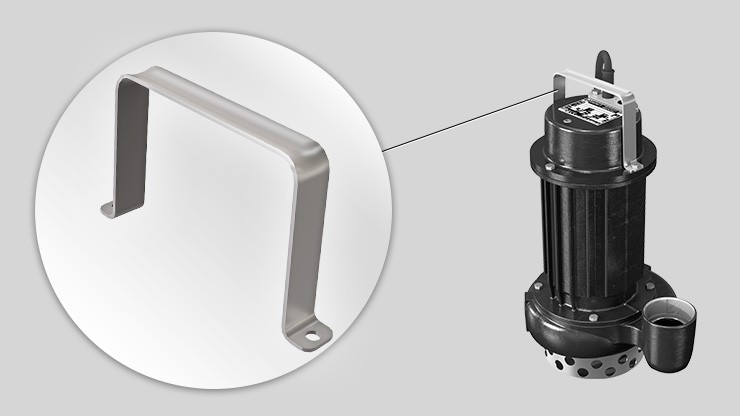

Cable gland

Case

Strainer

Dual protection

Motor

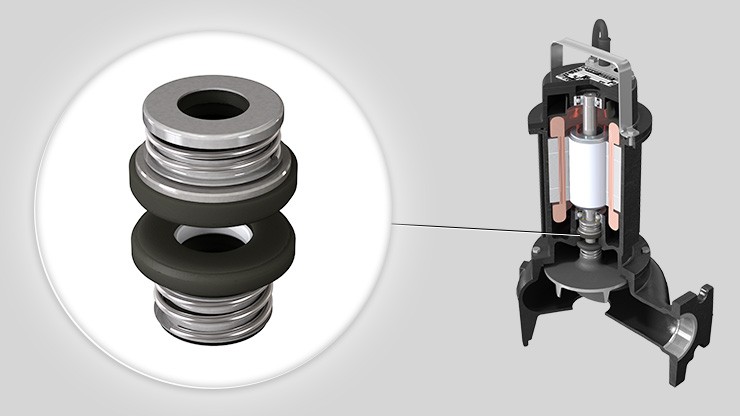

Mechanical seals

Free passage

Anti-clogging system

Operating ranges 50 Hz

Operating ranges 50 Hz

Operating specifications

Materials

Stainless steel lifting and carrying handle.

Stainless steel cable gland system which guarantees airtight sealand allows easy replacement of cable or float switch.

Robust cast iron construction.

Stainless steel suction strainer. [DRO]

The motor is protected by a bimetallic thermal protection in the stator and a overload protectioncurrent overload device (manual reset) installed in an external box. It cuts off the power supply in the event of current overload due to fouled impeller.

Oil-bath motor for effective cooling to allow even heavy-duty workloads.

One mechanical seal in silicon carbide (SiC) and one in alumina graphite (AL), cooled by motor oil.

Ample free passageallowing the expulsion of solids and preventing fouling of the impeller. [DGO]

Hydraulics with Anti Clogging System (ACS)which ensures the removal of small suspended solids and prevents fouling of the impeller.[DRO]

- Max operating temperature: 40°C

- pH of treated liquid: 6 ÷ 14

- Viscosity of treated liquid: 1 mm²/s

- Max immersion depth: 20 m

- Density of treated fluid: 1 kg/dm³

- Max acoustic pressure: <70 dB

- Max starts per hour: 30

- Motor casing: Cast iron EN-GJL-250

- Impeller: Cast iron EN-GJL-250

- Nuts and bolts: Stainless steel - Class A2-70

- Standard gaskets: NBR rubber

- Drive shaft: AISI 431 stainless steel

- Painting: Bicomponent epoxy paint with high resistance to corrosion